- A visit to a watch factory. (Swiss trip 2011) - A visit to a watch factory. (Swiss trip 2011)

|

Ricky Lee |

1245 |

June 25, 2011 03:11PM |

Awesome stuff Ricky. REALLY impressive machines.

Awesome stuff Ricky. REALLY impressive machines.  (n/t) (n/t)

|

DJM |

149 |

June 25, 2011 03:48PM |

That they are..

That they are..  and I am not easily impressed in that regard! and I am not easily impressed in that regard!  (n/t) (n/t)

|

Ricky Lee |

131 |

June 26, 2011 08:30AM |

Impressive equipment... and a Condor with a Ducati 350 single...

Impressive equipment... and a Condor with a Ducati 350 single...

one of about only 3000 made..

PS.. here's one of my favorite lathes.

|

Flasharry |

150 |

June 25, 2011 03:57PM |

"Ducati 350-based single" might be more accurate. If ye'll note..

"Ducati 350-based single" might be more accurate. If ye'll note..

..Condor did cast their name into the tappet access coverplate.

And, to be fair, there were

significant differences compared to the Ducati mill. Lower compression

ratio (the better to run on low-octane fuel), modified oiling system,

etc. Still, it was pure Ducati at heart, no arguing that.

Quote

Flasharry

PS.. here's one of my favorite lathes...

Impressive!  Mind you, it's a mere pup compared to a really big lathe:

Mind you, it's a mere pup compared to a really big lathe:

Quote

www.hiwtc.com/products/huge-capacity-cnc-lathe-by-tacchi-16921-44267.htm

Manufacturer Tacchi

Model CTU 3500 x 19000

Year 1993

Control siemenssinumerik 880t

Swing over base plate 5100mm (16.73 feet)

Turning length 19000 mm (62.33 feet)

Feedrates 0 - 6000 mm/min

Spindle bore 160 mm (6.3 inches)

Spindle motor rating 90 kw

Spindle speeds 1?280 rpm.

Faceplate diameter 1500 mm (59.05 inches)

Headstock + tailstock positioning

1350 mm (53.15 inches) synchron. In x-axis direction

Carriage facing traverse x 1000 mm (39.36 inches)

Max. Workpiece weight 55 tonnes (metric) 4 station tool block

12 station turret with milling tools and Y axis

Separate milling attachment (arbour) tailstock with 420 mm (16.53 inches) quill diameter

Tailstock quill travel 200 mm (7.87 inches)

Chip conveyor

{Crodile Dundee mode}

That, my friend, is a lathe!

{/Crodile Dundee mode}

|

Ricky Lee |

129 |

June 25, 2011 04:47PM |

Indeed, that is a LATHE...

Indeed, that is a LATHE...

and here I am lusting for a 10" or so metal lathe and small vertical

milling machine.. (and a suitable shop of course..) What would I make?

Steam stuff, for sure.. (a nice horizontal mill engine would be a good

styart, once I got my skill level back up to something above its current

abysmal level..) Of course.. a simpler project would be a custom

stainless handle for my 1939 Gilette Tech razor, which with a good blade

shaves far better that any of the current multi-blade wonders..

|

Flasharry |

144 |

June 25, 2011 08:16PM |

Re: ..and here I am lusting for a 10" or so metal lathe and small vertical milling machine..

Re: ..and here I am lusting for a 10" or so metal lathe and small vertical milling machine..

A 10-incher is a good practical size.  And a vertical mill is the perfect complement for it! And a vertical mill is the perfect complement for it!

Quote

Flasharry

..a nice horizontal mill engine would be a good styart..

You

know, I'd love to have a horizontal boring mill, like that Dixi in the

main post. In their own way, they're THE Bee's Knees.  However, I must admit they're not exactly a paragon of versatility... However, I must admit they're not exactly a paragon of versatility...

Quote

Flasharry

Of course.. a simpler project would be a custom stainless handle for my

1939 Gilette Tech razor, which with a good blade shaves far better that

any of the current multi-blade wonders..

Ah, but could it keep pace with this  Razor? Razor?

Would you pay $100,000 for a razor?

$100,000 can buy many things: a brand new sports car, a boat, or a ridiculously luxurious vacation, just to name a few. But if you already have a new Audi in your driveway, a yacht at the marina, and just got back from a trip around the world, perhaps you'd rather drop your cold hard cash on a limited edition iridium razor. The pricey item is crafted by Zafirro, a company which seems to have just one product in its lineup, and just 99 of the "Zafirro Iridium" razors will be made.

The handle of the razor is made entirely of iridium, an extremely scarce and expensive metal that is so dense it could survive a drop into molten lava. Most iridium that appears on Earth is the result of crashed meteorites. The blades of the beast are made from artificially grown sapphire, making them hypoallergenic, not to mention many orders of magnitude sharper than your average Bic. The company boasts a 10-year blade life, and backs it up with free sharpening for a decade if the razor ever dulls.

The Zafirro Iridium, while promising "generations" of enjoyable use, is clearly made for the millionaire who already has everything. The company says the upgrade from a traditional razor to the $100,000 model is like changing from a CB radio to an iPhone, but unless your morning shave takes place at the mouth of a volcano, we're not sure it's worth it.

Original article is HERE.

A $100K razor!  Who'd have ever thunk? Who'd have ever thunk?

|

Ricky Lee |

115 |

June 26, 2011 08:22AM |

Re: but could it keep pace with this

Re: but could it keep pace with this  Razor Razor

I think it could.. The Tech is a classic design, and a great shaver,

with the right blade... More importantly, its the face prep and lather

that really make a difference..

1939 Tech: - in pretty good shape, and great shaver..

Then for a change we have my 1955 Slim, also a good razor:

and of course the best of the lot: 1940;s Dorko.. which gets used every once in awhile.

oh,, and the horizontal mill engine? I was think a Stuart #9 for a start..

|

Flasharry |

124 |

June 26, 2011 09:47AM |

Thanks for sharing such cool pics!

Thanks for sharing such cool pics! (n/t) (n/t)

|

itschris |

109 |

June 25, 2011 04:20PM |

My pleasure.

My pleasure.  (n/t) (n/t)

|

Ricky Lee |

127 |

June 26, 2011 08:31AM |

Nice

Nice  (n/t) (n/t)

|

wodo |

107 |

June 25, 2011 06:50PM |

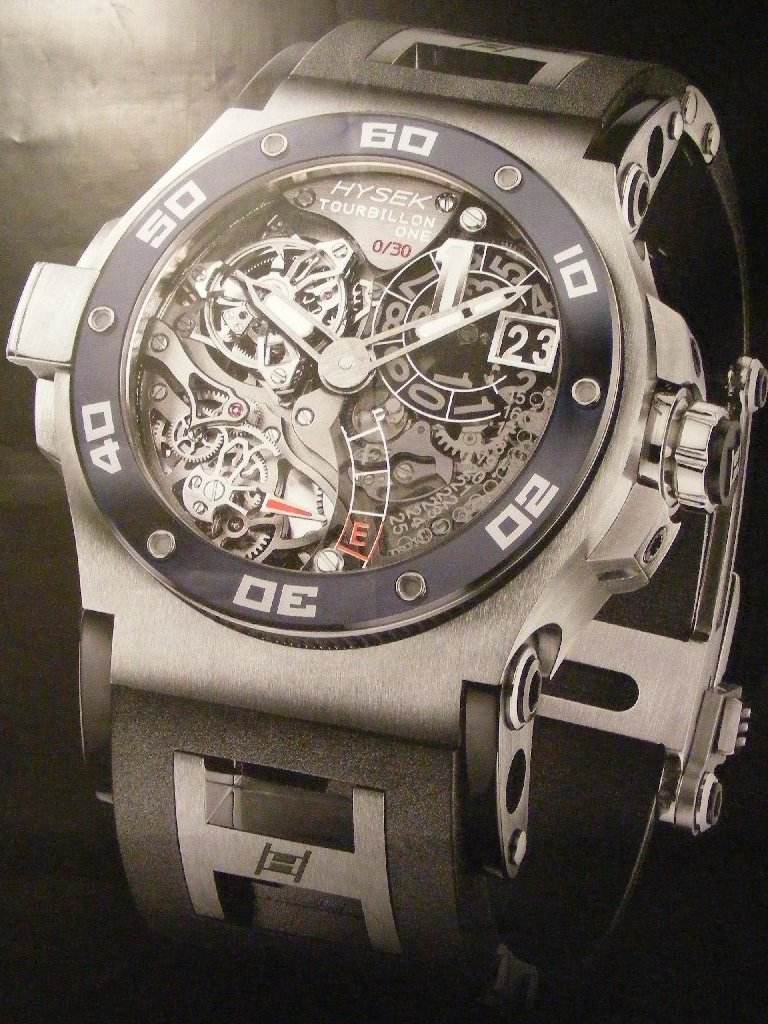

I really wish I could show you guys the prototype Hysek the Shop Manager was wearing.

I really wish I could show you guys the prototype Hysek the Shop Manager was wearing.

Talk about nice!

But a promise is a promise, and it's a wonder he let me shoot photos of it to begin with.

I got to say, though, it's killin' me  to have to sit on those photos! to have to sit on those photos!

|

Ricky Lee |

124 |

June 26, 2011 08:36AM |

Cool thanks. At first just looking at the pictures .........

Cool thanks. At first just looking at the pictures .........

I thought that was your basement.  That's some shop. That's some shop.

|

Robmks |

119 |

June 25, 2011 09:17PM |

Re: ..I thought that was your basement.

Re: ..I thought that was your basement.

If only it were so!

Quote

Robmks

That's some shop.

And that's actually only a small part of it!

|

Ricky Lee |

121 |

June 26, 2011 08:38AM |

Thanks for the great report!

Thanks for the great report!

That is indeed some impressive machinery.

I'm not sure I get why

the Rolex guy was upset. It wasn't a Rolex factory, right? Was his

upset-ness due to the fact that Rolex uses some of the same machines to

build their own watches?

|

Smaug |

133 |

June 25, 2011 10:30PM |

Re: I'm not sure I get why the Rolex guy was upset.

Re: I'm not sure I get why the Rolex guy was upset.

Thank you! I don't quite get it meself...

Quote

Smaug

It wasn't a Rolex factory, right?

Nope, 'twas the company that's building the machine for them (Bumotec S.A. in Sâles, Switzerland).

If it were a proprietary one-of machine, a R0lex design, then it would be understandable.  But it's a stock machine! Prominently displayed on the Bumotec web site!

But it's a stock machine! Prominently displayed on the Bumotec web site!

Quote

Smaug

Was his upset-ness due to the fact that Rolex uses some of the same machines to build their own watches?

They do

use S-1000 machines already, this is simply an additional machine to

expand their capacity. And plenty of other high-volume watch

manufactures use the S-1000 as well, ye'll note. Again, a custom one-of

machine tool would have been another thing.

Honestly, I don't know. As it was, I reckon the guy was pretty much just being a d1ckhead  because he could. because he could.

|

Ricky Lee |

148 |

June 26, 2011 08:53AM |

Cool machines! BTW that equipment would also be cheaper than Jessica too.

Cool machines! BTW that equipment would also be cheaper than Jessica too.  (n/t) (n/t)

|

Timemiser |

119 |

June 25, 2011 10:40PM |

They are NOT inexpensive machines, mind you.

They are NOT inexpensive machines, mind you.

Indeed, you could buy three conventional mid-sized 5-axis milling machines from a reputable  manufacture for what you'd spend on one S-191. Or a whole bloomin' rank and file of 3 and 4-axis machines! manufacture for what you'd spend on one S-191. Or a whole bloomin' rank and file of 3 and 4-axis machines!

Still, it wouldn't be all THAT hard to exceed the purchase price of an S-191 on a truly high-zoot watch or automobile.

But you're no doubt right in that an S-191 would be $$ peanuts compared to the maintenance costs of that particular  model. model.

|

Ricky Lee |

130 |

June 26, 2011 09:07AM |

Wow! A really watch -wis- related topic! Top topic!!!

Wow! A really watch -wis- related topic! Top topic!!!   (n/t) (n/t)

|

IF |

123 |

June 26, 2011 05:22AM |

Bro. Yannis! Bro. Yannis!

BTW, did I miss your Full Report on the 2011 Matala Hippie Reunion?

Or is it still in the works...?

|

Ricky Lee |

131 |

June 26, 2011 09:13AM |

Ricky I had....

Ricky I had.... .............. ..............

......., no time to take any pics, my good camera is still broken, we

had to do a lot, everything went O.K. There are many things about it in

the internet, the facebook of our site(visitmatala.com), in youtube of

course, e.t.c.....

I am really sorry again, I have no report to make,.......

|

IF |

102 |

June 26, 2011 02:20PM |

Ah well, I understand. No doubt you were busier'n a 1-legged man in a butt-kickin' contest.

Ah well, I understand. No doubt you were busier'n a 1-legged man in a butt-kickin' contest.

Tell ye what, I'll waive the use of the Dread TTIWWOP Icon, and settle for an amusing anecdote or two..

|

Ricky Lee |

118 |

June 26, 2011 07:47PM |

Ricky: Thanks for a look into a side of watchmaking that few of us think about. (n/t)

Ricky: Thanks for a look into a side of watchmaking that few of us think about. (n/t)

|

johnizy |

119 |

June 26, 2011 07:33AM |

You know, it's funny.. You know, it's funny..

..I suppose it's true that not many WIS

think about the manufacturing side. Even highly-skilled watchmakers who

have no trouble disassembling and reassembling a complex mechanical

movement may not be knowledgeable about (or even interested in) the

special challenges involved in volume manufacturing of the same.

But as a manufacturing professional it seems perfectly natural to me, and I can't help but be intensely interested in that aspect of horology. Indeed, it was that side of the business that led me into this mad hobby in the first place.

|

Ricky Lee |

130 |

June 26, 2011 09:28AM |

Don't hessitate to indulge us even more. Thanks again. (n/t)

Don't hessitate to indulge us even more. Thanks again. (n/t)

|

johnizy |

116 |

June 26, 2011 12:17PM |

What a great post! Thanks hugely for taking the time to put that together. Great read

What a great post! Thanks hugely for taking the time to put that together. Great read  (n/t) (n/t)

|

nkwatchy |

137 |

June 26, 2011 07:40AM |

Thanks mate!

Thanks mate!

I hugely enjoyed putting it together, though, so no thanks are really needed.

|

Ricky Lee |

124 |

June 26, 2011 09:32AM |

mind blowing, could be the final statement of pennies to watches $$ to tools (n/t)

mind blowing, could be the final statement of pennies to watches $$ to tools (n/t)

|

Cleans Up |

115 |

June 26, 2011 02:05PM |

I

hope you don't think it hubris when I say that, given just one of those

machines, I could achieve a sort of One-Man Mini-Renaissance in

American Watchmaking.

I

hope you don't think it hubris when I say that, given just one of those

machines, I could achieve a sort of One-Man Mini-Renaissance in

American Watchmaking.

Or at least in Watch Case Making.

Sure I'd need a good partner when it comes to yon innards.

|

Ricky Lee |

107 |

June 26, 2011 07:53PM |

Glad i scrolled to the end. Glad i scrolled to the end.  (n/t) (n/t)

|

Larry |

105 |

June 26, 2011 04:36PM |

Think of it as a reward for having read through the boring stuff, all the way to the end.

|

Ricky Lee |

100 |

June 26, 2011 07:57PM |